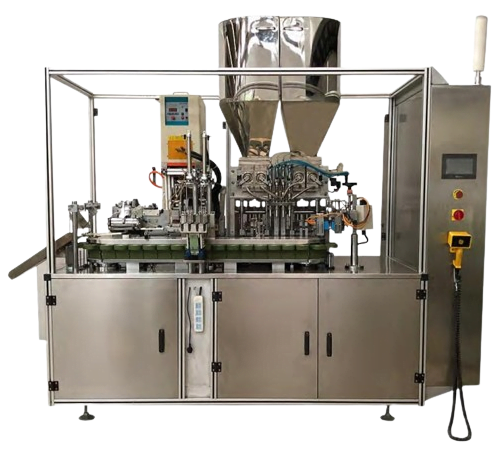

Tube filling sealing machine is widely used in pharmaceutical, cosmetic, food and chemical industries etc. Various products that can be filled by these tube filling machines such as cream, paste, liquid, adhesives, grease, sauce, & others. The tube filler sealer is mechanotronics mechanical-electrical integration, use multiple introduction technology and controlled by PLC, it can complete tube feeding, local color code, filling, sealing and tube out automatically simultaneously.

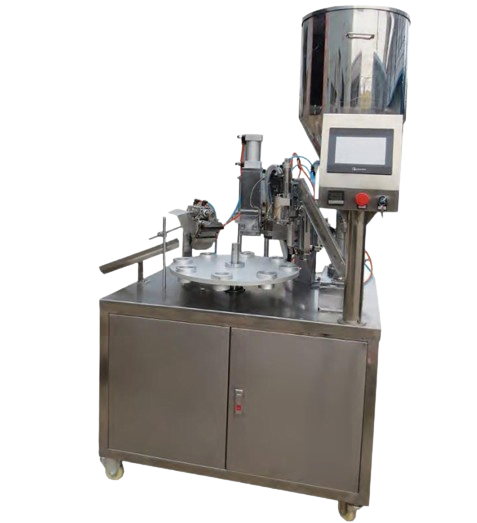

Productivity: 20-30pcs/min

Filling Volume: 8-250ml (change pump)

Filling Accuracy: ≤±1%

Tube Diameter: 10-50mm (change molds)

Tube Length: 50-200mm (customized)

Sealing Type: Heating (Plastic), Folding (Aluminum)

Max Power: 2KW (Plastic), 1.5KW (Aluminum)

Voltage: 220V/380V, 50/60Hz

Hopper Capacity: 40L

Control: PLC Control + Touch Screen

Feature: No Tube No Filling

Dimension (L*W*H): 1200*800*1600mm

Weight: About 500KG

Applications: Toothpaste, Ointment, Paste Food, Cosmetics, Hair-Dyeing, Adhesive, Art Palette, etc

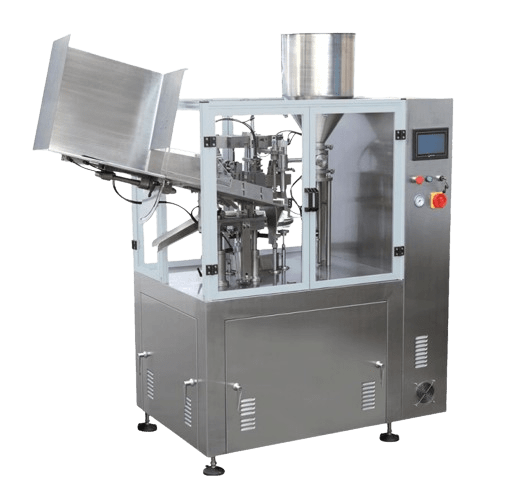

Productivity: 20-30pcs/min

Filling Volume: 8-250ml (change pump)

Filling Accuracy: ≤±1%

Tube Diameter: 10-50mm (change molds)

Tube Length: 50-200mm (customized)

Sealing Type: Heating (Plastic), Folding (Aluminum)

Max Power: 2.0-3.3KW (Plastic), 1.5KW (Aluminum)

Voltage: 220V/380V, 50/60Hz

Hopper Capacity: 40L

Control: PLC Control + Touch Screen

Feature: No Tube No Filling System

Dimension (L*W*H): 1000*800*1600mm

Weight: About 600KG

Applications: Toothpaste, Ointment, Paste Food, Cosmetics, Hair-Dyeing, Adhesive, Art Palette, etc.

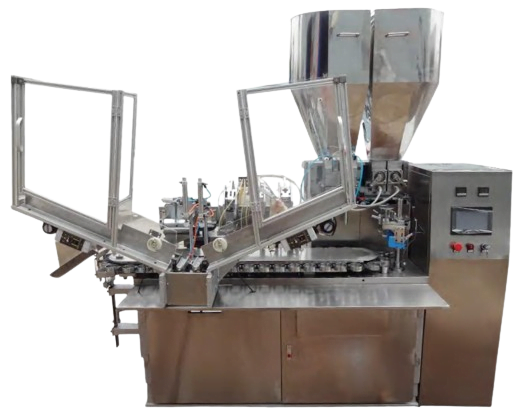

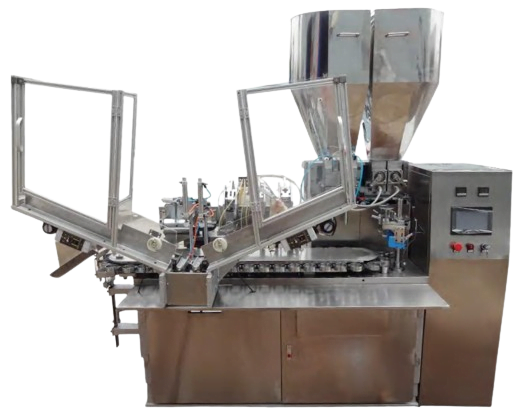

Productivity: 20-30pcs/min

Filling Volume: 8-250ml (change pump)

Filling Accuracy: ≤±1%

Tube Diameter: 10-50mm (change molds)

Tube Length: 50-200mm (customized)

Sealing Type: Heating (Plastic), Folding (Aluminum)

Max Power: 2.0-3.3KW (Plastic), 1.5KW (Aluminum)

Voltage: 220V/380V, 50/60Hz

Hopper Capacity: 40L

Control: PLC Control + Touch Screen

Feature: No Tube No Filling System

Dimension (L*W*H): 1000*800*1600mm

Weight: About 600KG

Applications: Toothpaste, Ointment, Paste Food, Cosmetics, Hair-Dyeing, Adhesive, Art Palette, etc.

Productivity: 30-80pcs/min

Filling Volume: 5-200ml (change pump)

Filling Accuracy: ≤±1%

Tube Diameter: 10-50mm (change molds)

Tube Length: 210mm (The Max.)

Sealing Type: Heating (Plastic), Folding (Aluminum)

Max Power: 2KW (Plastic), 3.3KW (Aluminum)

Voltage: Control: 280V/380V/50Hz/60Hz

Display: Feature: PLC Control System

Dimension (L*W*H): Touch Screen Display

Weight: No Tube No Filling

Industries: 2270*960*2100mm

About 850KG Cosmetics, Pharmaceutical, Dairy, Foodstuff, Adhesives, etc.

Productivity: 80-100 tubes/min

Filling Volume: ≤±1%

Filling Accuracy: 5-200ml (change pump)

Tube Diameter: 11-40mm (change molds)

Tube Length: 50-230mm (customized)

Hopper Capacity: 50L

Sealing Type: Max Heating (Plastic), Folding (Aluminum)

Power: Voltage: 7.5KW (Plastic), 1.5KW (Aluminum)

Control: 280V/380V/50Hz/60Hz

Display: PLC Control System

Dimension (L*W*H): Touch Screen Display

Weight: 2170*1100*2100mm

Features: About 1300KG Applies to the striped toothpaste filling, double color and three-color

Productivity: 80-100 tubes/min

Filling Volume: ≤±1%

Filling Accuracy: 5-200ml (change pump)

Tube Diameter: 11-40mm (change molds)

Tube Length: 50-230mm (customized)

Hopper Capacity: 50L

Sealing Type: Max Heating (Plastic), Folding (Aluminum)

Power: Voltage: 7.5KW (Plastic), 1.5KW (Aluminum)

Control: 280V/380V/50Hz/60Hz

Display: PLC Control System

Dimension (L*W*H): Touch Screen Display

Weight: 2170*1100*2100mm

Features: About 1300KG Applies to the striped toothpaste filling, double color and three-color

PProductivity: 120-150pcs/min

Filling Volume: 5-250ml (change pump)

Tube Diameter: 10-50mm (change molds)

Tube Length: 230mm (The Max.)

Filling Accuracy: ≤±1%

Sealing Type: Heating (Plastic), Folding (Aluminum)

Max Power: 9.5KW (Plastic), 2.3KW (Aluminum)

Voltage: Control: 380V 50Hz

Display: PLC Control System

Dimension (L*W*H): Touch Screen Display

Weight: 3147*1555*2267mm

Features: About 3800KG

Can be customized for 4 heads filling, high speed, high performance.

our company, is a reputable engineering organization situated in Malaysia, specializing in various aspects of the packaging industry. As a part of the CP Tech Packaging group, which operates from Shanghai, our expertise spans across filling, sealing, labeling, packaging, and end-of-line equipment.

WhatsApp us